LOVOL's commitment to innovation stems from its strong global research and development presence and its unremitting pursuit of advancing agricultural technology.

2500+

R&D Personnel

2140

Patented Technologies

$140million

Annual R&D Investment

130

National Scientific Projects

ACHIEVEMENTS

In recent years, LOVOL has made breakthrough progress in core areas such as CVT high-horsepower tractors and large-feed harvesting machinery, and continues to lead the industry in technology upgrades and product innovations.

FULL-CHAIN AGRICULTURAL MACHINERY

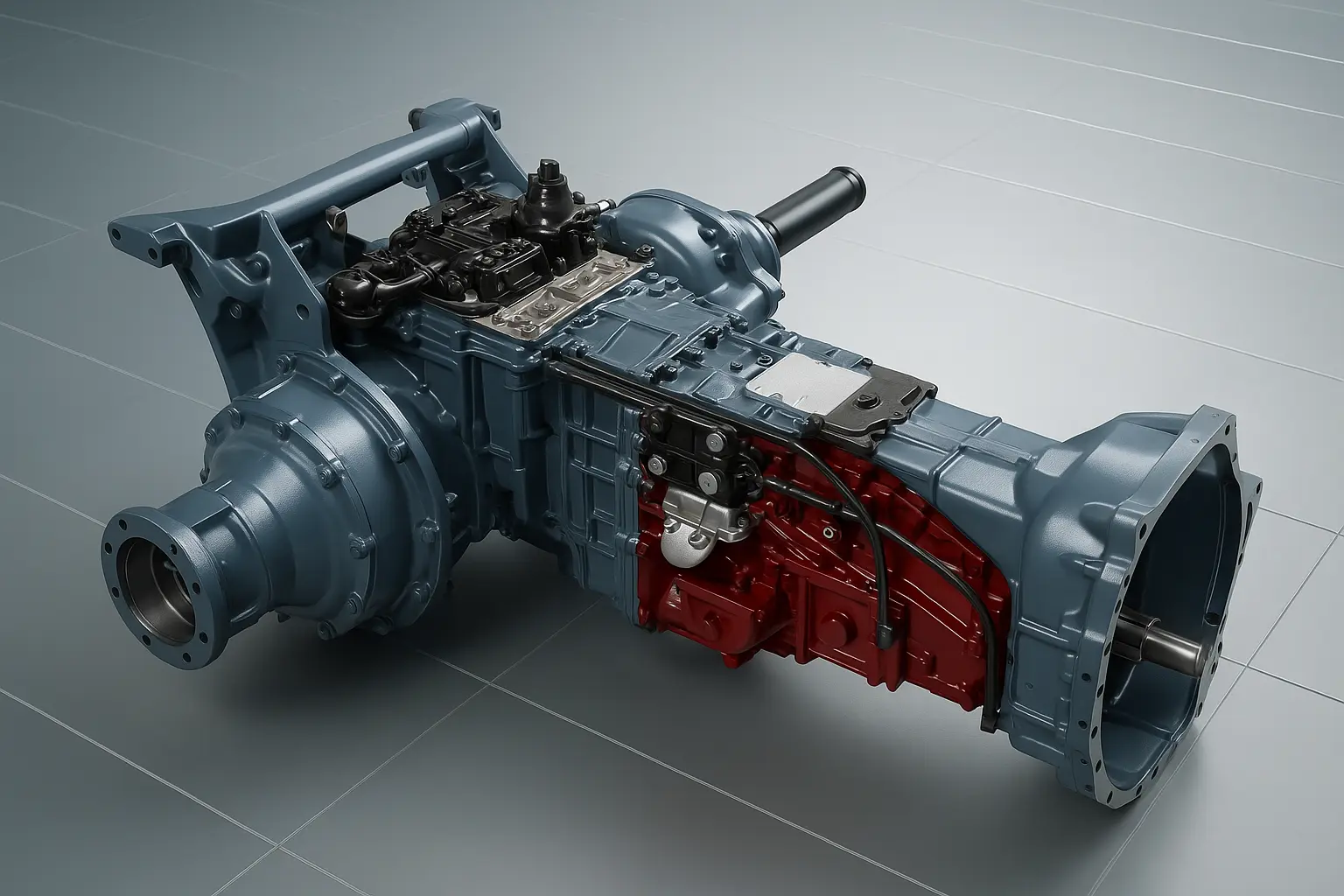

LOVOL integrates the group's resource advantages to create a full-link self-developed agricultural machinery Golden Power Chain® of "Weichai engine + Linde hydraulics + Hande axle + Fast gearbox". It has achieved self-development of core technologies and core components and is the only agricultural machinery brand in China that controls the key technologies of the entire industry chain.

CVT HIGH-HORSEPOWER TRACTOR

LOVOL is the first and only agricultural machinery brand in China with independent intellectual property rights for CVT, and has taken the lead in commercializing 180-380HP high-horsepower CVT tractors in China.

Compared with traditional tractors, the comprehensive operating efficiency of LOVOL CVT models is increased by 30%, achieving a perfect combination of optimal power and optimal fuel economy.

LARGE-FEED HARVESTER

LOVOL has independently developed a series of high-end harvesters with large feed volume, such as GM, GK, and GS models, with key breakthroughs in high-efficiency threshing and cleaning technology and intelligent operation technology, and has become one of the international first-tier harvesters in the field of high-end harvesters.

PRECISION MANUFACTURING, PROVEN RELIABILITY

MAIN FACTORY

Global Manufacturing Center

Location:Weifang, Shandong

Total Site Area:620,000㎡

Output:220,000 units/year

HIGH-HORSEPOWER INTELLIGENT TRACTOR FACTORY

Next-Gen Smart Factory Hub

Location:Weifang, Shandong

IMPLEMENT FACTORY

Dedicated Implements Plant

Location:Zhucheng, Shandong

Total Site Area:246,000㎡

Output:100,000 units/year

COMPONENTS FACTORY

The Backbone Plant

Location:Linyi, Shandon

Total Site Area:185,000㎡

Output:500,000 units/year

TRACTOR ASSEMBLY FACTORY

M-Platform Tractor Assembly

Location:Heilongjiang

Total Site Area:530,000㎡

Output:100,000 units/year

HIGH-END LARGE HARVESTER FACTORY

(under construction)

Location:Weifang, Shandong

PRECISION MANUFACTURING

LOVOL upholds uncompromising values, treating every product as a solemn commitment to our customers. We implement rigorous quality control at every manufacturing stage, ensuring full compliance with the industry's most stringent production standards.

HOW WE ACHIEVE EXCELLENCE

HIGH-TECH ACHIEVE HIGH-TECH

LOVOL represents the highest standard of manufacturing technology in China's industry, meeting the high-end quality requirements of global users.

Automated Production – 120+ assembly lines, 1,000+ fully automated robots.

Precision Correction – 0.5s real-time deviation correction (±0.02mm accuracy).

Smart Manufacturing – 100% MES coverage for full-process monitoring & scheduling.

UNCOMPROMISING QUALITY STANDARD

LOVOL ensures top-tier quality – from components to final assembly – with premium materials and a strict digital traceability system.

Smart Inspection – Industrial sensors & vision systems with 99.97% defect detection accuracy.

Full Traceability – Lifetime tracking with 100% quality data coverage for all parts.

Proven Durability – 800+ hours of certified operation without major repairs.

TEST-DRIVEN MANUFACTURING

LOVOL Test Center – 200+ test benches and multi-level inspection ensure peak performance. Before reaching you, every product passes:

48 hours of continuous running-in test of the whole machine

200 hours of laboratory working condition simulation test

More than 800 hours of standardized farm test

1000 hours of real user blind test

DEFINING QUALITY WITH STRICTNESS

LOVOL has set up a special "high temperature, high cold, high pressure" test team to push the performance of each device to the limit.

Extreme Heat – 80°C Turpan desert test (power system & chassis durability verified)

Extreme Cold – -42°C Heilongjiang test (hydraulic & electronic stability proven)

High Altitude – 5,000m Tibet plateau test (turbocharger hypoxia performance validated)

LOVOL – China's No. 1 agricultural machinery brand and a globally trusted leader in farm equipment, built on reliability and innovation.