The LOVOL TB series wheeled tractors are a kind of multi-purpose medium-sized farm wheeled tractors. They have such advantages as compact structure, easy control, smart steering, large traction force, extensive purposes, and convenient service and maintenance. If equipped with appropriate farm implements, they can carry out such tasks as plowing, harrowing, sowing, and harvesting; if equipped with trailers, they can carry out carry operations for agricultural purposes, but ensure that the trailer/towing vehicle mass ratio (the ratio between the total mass of the trailer and the complete machine mass of the tractor) should not be greater than 3; if connected with straw returning shredders through PTO shafts, they can carry out straw returning tasks; they can also serve as motive power of water pumps and threshers. Please match the farm machines and implements correctly according to the requirements in this manual (see Appendixes 11 table 11.5) to obtain the maximum economic benefits. The agricultural tractors can’t be used in conditions which may cause the risk of contact with hazardous substances, e.g. spraying of pesticides. In addition, the agricultural tractors also can’t be used in conditions which may cause risk of falling and penetrating objects.

Users shall observe the working, maintenance and service conditions specified by the maker as well as the essential requirements for the expected purposes strictly. Using this tractor for other operations will breach its expected purposes.

Have this tractor operated, serviced and maintained only by the personnel who are familiar with characteristics of this machine and command related safe operation knowledge.

You must observe the accident prevention rules as well as other safety regulations and road traffic rules at any time.

The manufacturer will never be liable for any reliability reduction or damage of the machine or personal injury resulted from any unauthorized remanufacturing of this machine or using this tractor for the tasks that breach its expected purposes.

No. | Unit category | International unit |

1 | Time | s |

2 | min | |

3 | h | |

4 | Length | mm |

5 | cm | |

6 | m | |

7 | km | |

8 | Force | N |

9 | kN | |

10 | Moment | N·m |

11 | Mass | kg |

12 | g | |

13 | Pressure | Pa |

14 | kPa | |

15 | MPa | |

16 | kgf/cm2 | |

17 | Temperature | ℃ |

18 | Velocity | km/h |

19 | Speed of rotation | r/min |

20 | Current | A |

21 | Voltage | V |

22 | Volume | L |

23 | ml | |

24 | Flow | L/min |

25 | Power | kW |

26 | PS | |

27 | Oil consumption | g/kW·h |

28 | Battery capacity | A·h |

1.1 Safety rules and notices of use

1.2 Safety warning symbols

3. Operation Instructions

3.2 Operating mechanism and instrument of tractor

3.6 How to gear shift tractor

3.7 How to operate differential lock

3.8 How to use front drive axle

3.10 How to stop tractor and how to flameout engine

3.11 Adjustment of wheel track

3.12 Tire (Radial tire) use and removal/installation

3.13 How to use counter weight

3.14 How to adjust driver’s seat

3.16 Use of working device of tractor

4. Accessories, spare parts and consumables

4.2 Documents, spare parts and facilities provided with the machine

5. Maintenance Instructions

5.1 Technical maintenance regulations

5.2 Operations for Technical Maintenance

5.3 Tractor Chassis Adjustment

6.1 Causes of the damages occurred during storage of the tractor

6.3 Maintenance during the tractor’s storage

7 Delivery, acceptance and transportation

7.1 Delivery and acceptance

8 Main technical specifications of tractors

8.2 Product Technical specifications

8.3 Theory speed of tractor

9 Disassembly and disposal

10.1 Product warranty basis

10.2 Cases not covered by the warranty policies

11.1Oils and Solutions Used on the Tractor (Table 11-1)

11.2 Tightening Torque Table of Major Bolts and Nuts (Table 11-2)

11.3 Reinforced, seal and O-ring seal (Table 11-3)

11.4 Rolling bearings (Table 11-4)

11.5 Supporting farm machines and implements (Table 11-5)

Customer Information Feedback Form

Tractor delivering training sheet

Tractor compulsory insurance service sheet

1. Safety precautions

1.1 Safety rules and notices of use

Considering safety during operation of the tractor, all divers, no matter how rich experience in driving they have, should carefully read and understand this manual. Do not operate the machine at any time until you have mastered the operational steps indicated in this manual. During operation, you should comply with the following notes as well as important security notices in this manual, such as ‘ warning,

warning,  notice, important issue and note’ etc.

notice, important issue and note’ etc.

Reading prior to use 1 The instructions for use and maintenance and the safety warning identifiers have to be fully read and understood. 2. The correct manipulation and operating method have to be kept in mind.

|

An qualified operator 1. When operating the machine, the driver must be able enough for sound judgment. 2. Persons feeling not well, drunk, short of sleeping, pregnant women, color blindness and those under 18 year-old are not allowed to operate the machine. 3. 4. In case of first driving, the operator is required to drive slowly before skilled. 5. When the machine is flameout and parked at the safety position, the driver can get on the tractor through left door or right door by steps. 6. The driver can leave the tractor through left door or right door by steps only when he has driven the tractor to a safety position and flamed out. |

Driver’s clothes 1. During operation, the drivers should wear tight fitting clothes; No loose working suits and shirts allowed, never put on neckties and necklaces, etc; long hair (if any) should be coiled up. 2. If you work on the site close to tractor or operating parts, coil up your hair (if any), never put on neckties, scarves or necklaces, etc. If these items are wringed into machine, this can cause serious injury.

|

Use of fuel 1. The fuel is the combustible substance, fire is strictly prohibited when in use. 2. Prior to tank refueling, the engine should shut down. 3. Smoking is strictly prohibited when the fuel system is refueled and overhauled. 4. Use clean rag to wipe out in case of fuel or machine oil overflow. 5. 6. It is forbidden to put flammable and explosive objects near the fuel tank orifice | |

Safe change of working fluid 1. The working liquid is dangerous and will cause serious personal injury, such as high-pressure hydraulic oil, brake fluid and engine oil, etc. 2. Prior to changing working fluid, it’s required to switch off engine and prohibit smoking; when any working fluid overflows, please wipe it with clean cloth. 3.Change working liquid based on correct brand. 4. The replaced working liquid is waste oil which cannot be discarded at will. |

Precautions for maintenance of tyre 1.Failure to mount and dismount the type according to specified procedures may cause explosion and subsequent serious casualties; therefore, don’t mount and dismount the type when there is no proper equipment and safe working experience. 2. The correct inflation pressure of tyre must be maintained; don’t exceed the specified max. inflation pressure of tyre. When the max.pressure is exceeded, it may cause crack at the edge of tyre and even explosion. When the recommended inflation pressure is reached, if the edges on both sides of tyre still haven’t been positioned, the tyre shall be deflated and re-positioned and its edge shall be lubricated for reinflation. 3. Inspect and retighten the tightening torque of fixing nuts and bolts of front and rear rims on a regular basis to prevent turnover of vehicle, serious injury of operator and serious damage of machine due to coming off of wheel. |

Disposal of waste oils and wastes 1. Improper disposal of waste oils and wastes will threaten the environment and ecological environment. 2. When the waste oil is discharged, the leak proof container shall be used; the waste oil is not allowed to be placed into the container which is used to contain food and drink to prevent drinking accidentally by others and leading to accidental injury. 3.It’s prohibited to pour the wastes onto the ground and into sewer and other water sources.

|

Passing beneath living and industrial power cables

1.Every part of machine shall be fixed firmly to prevent looseness and resultant electric shock.

2.When passing beneath the hanging living and industrial power cables at a low speed, it’s required to ensure that the height of the highest point of machine conforms to the allowable safety height of cable so as to avoid touching the cable and prevent electric shock.

3.The machine is prohibited to collide with high-voltage line when it’s in transport,working and shutdown state to prevent electric shock hazard.

1.Parts or implement should fall to ground. If the tractor or its parts must raise, they must be supported safely. 2.Don’t use cinder, air brick, tile or other supports which are easily disintegrated under persistent pressure to support the machine. 3.Don’t work under the tractor which is supported by only one jack. 4.Before operating the jack, it is necessary to read the operation

5.The jack should support just below of tractor rear-axle left and right semi-shaft shell. Other parts are notallowed to support.

|

Emergency exit of the cab

|

In addition, the driver can use the breaking tool to break the big enough glass to leave the tractor under the emergency situation. |

1. When the machine is operating, please don’t lubricate, maintain, repair or adjust it; these operation shall not be executed until all the parts stop moving. 2. Keep the hands, foots and clothes away from moving transmission parts.

|

Pay attention to hydraulic pipeline 1. The high-pressure hydraulic oil has enough force to penetrate and damage the hands, eyes and skins, therefore, prior to inspecting and maintaining hydraulic pipeline, it’s required to inspect the possible leakage point by paperboard or woodboard after the pressure of hydraulic system is relieved so as to prevent injury of hands and body by high-pressure fluid.

3. Heating near pressurized fluid pipeline will generate flammable spray and cause serious burn to him/her or the adjacent persons. Therefore, please doesn’t heat near the pipeline. It’s prohibited to heat by electric welding, gas welding or welding torque near pressurized fluid pipeline or other flammable materials, because the thermal radiation other than flame will damage the pipeline accidentally. |

Riding of others 1. Only the driver is allowed to operate the machine; all other persons are not allowed to take the machine without assistant seat, and the machine with assistant seat is allowed to carry one passenger only, but in no case this will interfere, influence and block the operating activity of driver. 2. Under starting and working state of machine, anyone is not allowed to go up and down or climb up the machine, and shall be kept away from the machine to avoid injury. |

Disposal of emergency event 1. In case of brake failure, it’s required to stabilize the steering wheel, drive the vehicle to a safe place and shut down the engine immediately. 2. In case of faulty steering wheel, please apply the brake immediately and shut down the engine.

4. In order to ensure personal safety of you and others, please don’t risk driving or operating. After the machine is well repaired and when the surrounding environment is safe, the operator shall restart and have it move slowly. 5. In case of fire, you shall shut down the engine immediately. Use fire extinguisher, if any, to spray towards the root of flame; if no any fire extinguisher, the sands can be used for fire fighting. |

Upon connecting with other devices or changing of components for tractor 1. Upon changing of components, you must shut down the engine and park the tractor onto a safe place for changing. Prior to changing, please carefully read safety sign and operation instruction, if necessary, the professional personnel shall be invited for change. 2. When the tractor is connected with other devices, the personal injury may be caused if lack of necessary experiences, therefore, the professional personnel shall be invited to execute connection if necessary. |

Correct use of battery

2. The battery shall be used for other applications other than engine starting. 3. When the battery is charged or changed, please read the notice label on the battery. 4. When the battery is removed, please remove the bond strap that is connected with negative terminal (-) shall be removed. After battery is mounted, the cable that is connected with positive terminal (+) shall be installed firstly. 5. When the battery is charged, it shall be removed. 6. Prior to charging, please inspect whether the vent hole on the battery cover is well ventilated, with ventilated surrounding environment. 7. Properly select charging current according to rated capacity of battery. After charging, please disconnect charging source firstly and disconnect cable from the terminal of battery to prevent that the battery is detonated by electric firing. 8 Please don’t use any other batteries other than the one designated by the machine.

②Avoid breathing smoke generated by electrolyte; ③Prevent splashing or leakage of electrolyte; ④Use correct parallel starting procedures. |

Maintain correct mounting of anti-rollover frame

If the anti-rollover frame is disengaged or removed due to any reason, please make sure that all the parts and components can be reinstalled correctly. Tighten the fixed bolt to the correct torque. If the structure of anti-rollover frame is damaged due to overturn accident and bending, its protection function will be influenced, so the damaged anti-rollover frame must be replaced and not be used any more.

Correct use of foldable anti-rollover frame and safety belt

1. If the tractor has a foldable anti-rollover frame, the anti-rollover frame must be kept in the fully extended and locked position. If the anti-rollover frame of tractor works when it is in folded position, carefully drive the tractor. If the anti-rollover frame is in the folded position, it’s not allowed to use seat belt.

2. If the normal working conditions of tractor are recovered, the anti-rollover frame must be lifted to the fully extended position and fixed immediately. When the anti-rollover frame is in fully-extended or locked position, the safety belt must be used.

3. If the mounting fasteners, retaining ring or retractor has any damage, the whole safety belt must be replaced.

4. Inspect safety belt and its mounting fasteners frequently. Check whether the fasteners are loose or safety belt is damaged, such as incision, scratch, abnormal damage and abrasion.

5. If no anti-rollover frame or driving cab is provided, it’s prohibited to use safety belt.

Cautions when installing the implement or dragging the trailer

1. When installing the dragging implement or trailer, the engine should stop and the tractor should park at the safety position. Please read implements or trailer’s installing instructions, signs and operating manuals carefully before changing.

2. The operation should be carried out according to the operating manual. Before finishing installing the dragging implement or trailer, it is forbidden to operate the tractor which is installed implement or connected trailer.

3. When connecting the dragging implement or trailer to tractor, it maybe cause personal injury if the person is lack of necessary experience. So the professional should be invited when necessary.

4. The implement should have fallen to ground before people leaving the tractor.

5. People should keep away from the areas between tractor and trailer when tractor is working with trailer.

1. Please hold your safe operation for sake of your life, property security and family happiness. 2. When the tractor starts up, the attention should be paid to whether there is the obstacle on path, anyone present between tractor and farm tool or trailer, to prevent from the sudden start of tractor, action out of control, which will cause the accident risk; 3. Do not leave the pilot seat to start and operate the tractor. Be sure that various shift levers stay in the neutral gear position prior to the startup and the PTO control handle and drive handle on the disconnecting position, the lift operating handle put in the neutral position, to prevent from the sudden start, action out of control, which will cause the accident risk. 4. Do not start up the engine by the way of bridge-over short circuit stubs, otherwise, the tractor will automatically loose control on driving and cause the accidental danger when the gearbox is engaged. 5. The pedal action should not have any hindrance; all of pedals must be free from obstacles and able to back on home position. On the floor and under the pedal, there must not be any things hindering the treadle travel. No rolling or slip objects may lay aside when steps on the pedals. The extra foot blanket or other mats are not allowed to lay around the pedals, in order to avoid the influence on the pedal movement and cause the accidental risk. 6. While the tractor is moving, persons are not allowed to get on and off. During the engine run, no check and repair operations by crawling under the bottom of the tractor are permitted for prevention from the accidental risk. 7. After parking and before getting down from the tractor, the driver must take out the key, set all shift levers on the neutral position, and lock up the auxiliary brake handle to prevent the tractor from the sudden startup, action out of control and accidental risk. 8. During the operation, the L/R brake pedals must chain-linked and the speed reasonably under control. When crossing the tunnels and the bridges, full attention must be paid to whether the load is over the limited height. The sufficient deceleration must be made in advance while turning to avoid the accident, overturn and collision. 9. Onand down slop, the lowest gear must be used and the use accelerograph reasonably controlled. It is strictly prohibited for the tractor to shift on neutral gear or to glide downhill by stepping on the clutch pedal. It is strictly prohibited for the gear shift on and down slop so as to avoid the danger of overturn. 10. The sudden turn is not allowed while the tractor drives on high speed. Do not make the sudden turn by the unilateral braking, to avoid the danger of overturn. 11. By driving the tractor, the attention should be paid to the traffic indication and the traffic law and rules strictly observed, in order to avoid the accidental safety hazard. 12. In case of tractor displacement, the traffic rules should be strictly observed with at least 60mts of distance maintained between vehicles, to avoid the collision by accident. 13. The roadbeds near ditches, caves are more fragile, the tractor's weight possibly causes their crushes, please make a detour, otherwise the accidental danger may arise. 14. The tractor is not allowed to the overload and the excess use of load. It is prohibited to run over limit duty, which may cause the machine damage, even the casualty of present persons. 15. When tractor works at night, the good lighting attachment must be provided in order to avoid the influence on the tractor work efficiency and dangerous accidents. 16. When the tractor carries on the harvest or backyard work, The spark extinguish device must be fixed on the exhaust pipe , in order to avoid the accidental fire. 17. When working on rain day, The operation rate must be reduced to prevent the path and ground from creating slippery and the danger of overturns. 18. When the operation of dynamic output is carried out, the reliable connection and protection must be guaranteed to avoid the moving parts for shaking off and injuring persons. 19. When hitching and towing the attached tools, the reliable and fast connection of pin rolls must be guaranteed to prevent them from shaking off and causing the danger of collision. When disconnecting the hitch and towing tools, be sure that all pin rolls apart and avoid the damage on the machine and human safety danger by the misconnection. 20. When lifting, be careful of the control on the engine throttle to avoid over-speed of winding, which may damage the machine or endanger the personal safety. 21. During the battery charge, Make sure that the air outlet of fluid injection fills is unimpeded and far away from the open fire. After charge, the power should be first cut off to prevent from explosion. 22. The installation height allowed by the High voltage transmission line must be strictly observed, in order to avoid the dangerous accident! 23. Don’t use the tractor when it has the danger to turn over in dangerous area. 24. Just when the tractor finishes working, it is necessary to prevent oil heat surface to splash when people add oil or coolant to engine or transmission. 25. When operate three-point hitch, people should keep away from the hitch working area. 26. The implement should has already fallen to the ground before disconnecting it from tractor. 27. According to the function of implement and trailer, the user can adjust PTO speed through PTO shift. PTO speed is 540/760 or 540/1000. 28. When using PTO drive shaft, it is necessary to remove PTO shaft-end cover and make sure that protecting cover installs correctly in the working area. 29. In any situation, it is prohibited to operate the tractor if there is a risk of turnover. 30. It is strictly forbidden to operate the tractor in stormy weather, otherwise the vehicle and person will be liable to injury caused by electricity shock. |

1. Bolts, nuts and easy loose components on each joint, e.g. the nuts on the front/rear drive wheels and those attaching the steering draw rod should be frequently checked. If loose, screws it tightly to avoid the dangerous accident. 2. When the tractor runs by dynamic output, the safety shield of power take-off shaft has to be installed. Persons are strictly prohibited to approach the Power take-off shaft. When the power take-off shaft is on load, the tractor is not allowed to make the sudden turn in order to avoid the damage on the universal joint or the power take-off shaft; When the Power take-off shaft is not in use, the handle should be made on separate position, to avoid the dangerous accident. 3. After parking and before shut down from the tractor, the driver must take out the key, set all gearshift levers on the neutral position, and lock up the brake handle, to prevent the tractor from the sudden startup, action out of control and accidental danger. 4. When compelled to park on slop, the hand braking handle should be in active state, let the engine shut down, put on gear (Uphill position on front gear, downhill on reverse gear position),The auxiliary brake must be used with three pieces of triangle chocks blocking the rear wheels, to prevent from the action out of control and the accidental risk. 5. The installation and adjustment of tires can be carried out by the trained persons with special-purpose tool. The wrong installation of tires may cause the serious accident. 6. When the water tank is to be cleaned up, the engine should be first shut down and lets the water tank cool for cleaning, in order to avoid the scald accident and the damage on the water tank. 7. Before the selection for installing and replacing the parts, or for safe use by towing the machine and tool, please pay attention to the safety and carefully read the safety identifiers and the instruction for use. 8. Make sure that children are away from the tractor, machine and working area and are supervised by other adults. In any case, children are prohibited from riding or driving the tractor. |

Important: 1. For the tractor from the new production or after the overhaul, the running-in has to be made according to the requirements of tractor’s running-in, in order to avoid the affects on the normal service life of tractor. 2. The tractor should use various kinds of solution strictly according to the request. The fuel must be subject to at least 48h (hours) sediment and purification process. Only having passed through the filtration by filter at the same precision as that of oil absorption filter of lifter, that the lubricating oil in the transmission system can be added. 3. Prior to the startup of tractor, the oil system, electric circuit and the cooling water have to be examined; After the startup, the attention has to be paid anytime to the readout of various instruments. 4. Before the power take-off shaft actuates the farm tool, the matching rationality between the tractor and driven farm should be inspected. When tillage is performed, the included angle between the power take-off shaft and the universal joint drive shaft should not be bigger than 15° (grad); When the hydraulic operating control is normal, and after the farm tool has been lifted at the curve of field edge, the included angle between the power take-off shaft and the universal joint drive shaft should not be bigger than 20° (grad); It is prohibited to dig the Rototiller into field prior to the power take-off connection, for this will cause the damage on the Rototiller and severe damage on the tractor clutch [To increase the work efficiency, the power supply can not be shut off at the time of curve, however, the lifting height of tools must maintain ca. 200mm above the ground (millimeter)]. 5.When the temperature in winter is lower than 0℃(degree Celsius), the anti-freezing fluid must be used; 6. The front drive axle of tractor can be used only at the time of farmland work, on muddy road and skidded tires; the use on other cases is not allowed, otherwise it is easy to create the premature wear of tire and the power transmission. 7.During the running process of tractor, driver's foot are not allowed to place on the brake pedal or the clutch pedal, in order to avoid the premature wear of the brake or the clutch; 8. When the tractor displaces with attached farm tools, the upper lever of the suspension unit should be adjusted to the shortest condition, and the limit lever Adjusted to prevent the farm tools from swinging. At the meantime, the locking nuts of upper and limit levers must be tightly screwed in order to guarantee the travel security and avoid the damage risk on the machine and farm tools. 9. The tractor is hanging the farm tool shifts when should farm tool position locking; The farm tools must be lower on the ground when the driver leaves the tractor. 10.For the tractor maintenance, the qualified spare-parts must be used; |

When the Engine remains on warm state, care should be fully taken when twisting off the radiator cap. After several minutes of idle regime rotation and engine shutdown and cooling, twists the radiator cap to the first gear position, then takes it out after the pressure has been reduced. |

Maintenance of electric parts 1. Takes out the electrical locking switch key. 2. Only the electric appliance service can be carried out after the earth wire has been separated from the battery. 3. It is dangerous to touch electrolyte (dilute sulfuric acid). If eyes, skin and clothes touch the electrolyte, please wash with water immediately. If the electrolyte enters into eyes, please |

In case of abnormal phenomenon occurred on the tractor 1. The tractor is not allowed to work “in spite of defects”.In particular, on lack of oil pressure, excessively low oil pressure, over-high water temperature or unusual sound and smell, stops the work in time for check-up and troubleshooting. 2.

|

Safety rules for unattended tractor 1. Engage neutral gear and place the hydraulic operating handle to the middle position. 2. Place the lifting device or towing device onto the lowest position. 3. Apply parking brake. 4. Remove engine switch key. 5. If the vehicle is parked on a slope, its rear wheel must be blocked with triangle block. |

1.2 Safety warning symbols

Caution: 1. 2. When the safety identifiers lose or are unclear, it is necessary to contact the sales department or the manufacturer in time for replacement. 3. In case of replacing the parts with attached Safety warning symbols, the replacement of safety identifiers should be made at the meantime. 4. The safety warning identifiers, where the prompts involve to the personal safety, must be strictly complied. |

Meaning: During the machine operation, please keep the distance with the thermal surface of machine; otherwise it may cause the scald accident! Post position: outer side of muffler.

|

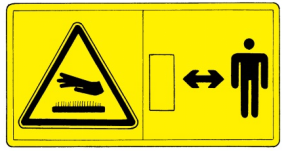

Meaning: Please keep the safe distance with the tractor, to avoid the personal injuries! Post position: left from the rear side of mudguard

|

Meaning: it is prohibited to sit on the non-crew member position in the tractor, otherwise it may cause the accident of falling from vehicle! Post position: front side of the mudguard .

|

Meaning: When the lifting lever control system works, stays far away from the effective space of lifting lever, otherwise it may cause the personal injuries! Post position: right from the rear side of mudguard

|

Meaning: prior to the service, maintenance and adjustment, the engine should be shut down, the key taken out, then perform according to the requirements set out in the instruction for use. Post position: in front of the instrument panel.

|

Meaning: When the engine works, do not hand into the working area, and do not open or dismantle the safety hood. Post position: on the surface of the generator hood.

|

Meaning: The driver must start up the engine on the pilot seat. Post position: in front of the instrument panel.

|

Meaning: Please read the instruction for use, understand the meaning of the non-lettered safety symbol. Post position: in front of the instrument panel.

|

Meaning: only fully stopped that all parts of machine can be contacted. Post position: on the shield of PTO.

PTO safety identifiers |

Post position: near the electric appliance box.

Fuse safety warning symbol |

Meaning: the battery is held on service, please read the instruction for use to understand the correct maintenance process. Post position: on the surface of the battery.

Battery symbol |

Post position: near the inlet of fuel tank

Refueling fire protection identifiers |

Post position: near PTO shaft

PTO safety identifiers |

Post position: on the pneumatic brake gasholder.

Pneumatic brake warning identifiers |

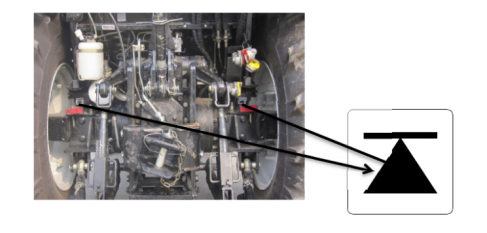

Schematic diagram for pasting of warning label 1-17 Safety warning identifier IV 1-18 Safety warning identifier II 1-19 Safety warning identifier VI 1-20 Safety warning identifier III 1-21 Safety warning identifier I 1-22 Safety warning identifier IX 1-23 Safety startup symbol 1-24 Read the instruction identifiers 1-25 PTO safety identifiers 1-26 Battery symbol 1-27 Fuse safety warning symbol 1-28 Refueling fire prevention identifiers 1-29 PTO safety identifiers 1-30 Pneumatic brake warning identifiers |

3. The traffic rules and the safety advices must be observed.

3. The traffic rules and the safety advices must be observed. . The driver should have received the special training, acquired the driving license and subject to the proof-test on time.

. The driver should have received the special training, acquired the driving license and subject to the proof-test on time. 3. During operations, it is necessary to wear protective tools such as safety shoes, safety helmet, goggles and gloves.

3. During operations, it is necessary to wear protective tools such as safety shoes, safety helmet, goggles and gloves. The requirements set out in the “Appendix” must be strictly complied with for the fuel and the lubricating oil quality.

The requirements set out in the “Appendix” must be strictly complied with for the fuel and the lubricating oil quality. 4. The wasted engine oil, fuel, refrigerating fluid, braking fluid, filter element or battery with potential hazard shall not be discarded at will; please consult local environmental protection environment or recycling center to recycle or dispose wastes in a correct way.

4. The wasted engine oil, fuel, refrigerating fluid, braking fluid, filter element or battery with potential hazard shall not be discarded at will; please consult local environmental protection environment or recycling center to recycle or dispose wastes in a correct way. Correct support of tractor

Correct support of tractor manual. It is forbidden to overload. The jack should be on the hard ground to prevent personal injury or property loss.

manual. It is forbidden to overload. The jack should be on the hard ground to prevent personal injury or property loss. The cab has three exits which are left door, right door and rear window. The rear window is the emergency exit (see the fig). Under the emergency situation, the driver can open the rear windowby rotating rear window unlocking handle clockwise to leave the cab.

The cab has three exits which are left door, right door and rear window. The rear window is the emergency exit (see the fig). Under the emergency situation, the driver can open the rear windowby rotating rear window unlocking handle clockwise to leave the cab. Avoid touching moving part

Avoid touching moving part 2. If anyone gets hurt by leaked hydraulic oil, he/she shall be sent to the hospital for treatment, and failure to receive necessary treatment may cause serious infection and reaction.

2. If anyone gets hurt by leaked hydraulic oil, he/she shall be sent to the hospital for treatment, and failure to receive necessary treatment may cause serious infection and reaction. 3. A first-aid kit shall be kept near you at all times, and the emergency telephone numbers of emergency center, hospital and fire department shall be available at any time. After the accident, you shall call emergency telephone of local emergency center, hospital or fire department as appropriate.

3. A first-aid kit shall be kept near you at all times, and the emergency telephone numbers of emergency center, hospital and fire department shall be available at any time. After the accident, you shall call emergency telephone of local emergency center, hospital or fire department as appropriate.  1. The gas overflowed from the battery is dangerous, therefore, the battery shall be kept away from open fire(fire from match, lighter or cigarette, etc); the electric line shall not have a short circuit and generate spark.

1. The gas overflowed from the battery is dangerous, therefore, the battery shall be kept away from open fire(fire from match, lighter or cigarette, etc); the electric line shall not have a short circuit and generate spark. 9. It’s very dangerous to contact electrolyte (dilute sulphuric acid). If eye, skin or clothes contact with electrolyte, flush it with clean water at once; when it goes into the eye, wash it with plenty of clean water and seek medical attention. The following measures shall be taken in order to avoid damage:

9. It’s very dangerous to contact electrolyte (dilute sulphuric acid). If eye, skin or clothes contact with electrolyte, flush it with clean water at once; when it goes into the eye, wash it with plenty of clean water and seek medical attention. The following measures shall be taken in order to avoid damage: ①Wear goggles and rubber gloves;

①Wear goggles and rubber gloves; Warning:

Warning: Caution:

Caution: Twists off the radiator cap

Twists off the radiator cap wash with a lot of water immediately and go to see a doctor.

wash with a lot of water immediately and go to see a doctor. During the lubrication maintenance and adjustment on field, the engine should be shut down.

During the lubrication maintenance and adjustment on field, the engine should be shut down. The safety identifiers should remain clear and easy to read. When dirty, washes with soapy water and cleans them with soft rag;

The safety identifiers should remain clear and easy to read. When dirty, washes with soapy water and cleans them with soft rag; Safety warning identifier IV

Safety warning identifier IV Safety warning identifier II

Safety warning identifier II Safety warning identifier VI

Safety warning identifier VI Safety warning identifier III

Safety warning identifier III

Safety warning identifier IX

Safety warning identifier IX

Reads the instruction identifiers

Reads the instruction identifiers