INTRODUCTION

The LOVOL F4000 series tractor is a powerful and versatile agricultural machine designed for Australian farming conditions. With 90-110 horsepower, advanced transmission systems, and robust construction, these tractors deliver exceptional performance for a wide range of farming operations.

However, with great power comes great responsibility. Tractors remain the leading cause of fatalities and serious injuries on Australian farms. This safety guide provides essential information to help you operate your LOVOL F4000 tractor safely and efficiently.

Key Statistics:

- Tractors account for 63% of farm vehicle fatalities in Australia

- Rollovers and runovers are the most common causes of tractor-related deaths

- Proper training and safety precautions can reduce accident risks by up to 72%

BEFORE OPERATION

Operator Qualifications

Who Can Operate the LOVOL F4000?

- Operators must be at least 18 years of age

- Must have received proper training and hold a valid tractor operation certificate

- Must not operate the tractor if unwell, fatigued, or under the influence of alcohol or drugs

- Pregnant women, colorblind individuals, and those with certain medical conditions should avoid operating tractors

Training Requirements:

- Complete a recognized agricultural machinery operation course

- Familiarize yourself with the LOVOL F4000 operator's manual

- Receive specific training on the tractor's features and controls

- Practice operation under supervision before independent use

Personal Protective Equipment (PPE)

Mandatory Safety Gear:

- Safety Helmet: Approved industrial safety helmet (AS/NZS 1801)

- Protective Clothing: Fitted work overalls, no loose clothing

- Foot Protection: Steel-toed safety boots (AS/NZS 2210.3)

- Hand Protection: Heavy-duty gloves for handling equipment

- Eye Protection: Safety glasses or goggles

- Hearing Protection: Ear muffs or plugs (for extended operation)

Additional Recommendations:

- Long hair must be secured to prevent entanglement

- Remove jewelry, ties, scarves, and other loose items

- Consider high-visibility clothing for field operations

Pre-Operation Inspection

Daily Safety Check List:

Visual Inspection

- Check for any visible damage to the tractor body and components

- Inspect all safety guards and shields for proper installation

- Verify ROPS (Rollover Protective Structure) is correctly positioned and locked

- Ensure all warning labels and safety decals are present and legible

Fluid Levels

- Engine Oil: Check level with dipstick, maintain between MIN and MAX marks

- Coolant: Ensure proper level in the expansion tank

- Hydraulic Oil: Check reservoir level

- Transmission Oil: Verify level in transmission housing

- Fuel: Ensure sufficient fuel for planned operation

Tire and Wheel Inspection

- Tire Pressure: Check and adjust to recommended levels

- Front tires: 180-200 kPa

- Rear tires: 120-150 kPa

- Tire Condition: Inspect for cuts, punctures, or excessive wear

- Wheel Nuts: Check torque (400-500 N·m) and tighten if necessary

Safety Systems Check

- Seat Belt: Ensure proper operation and no damage

- Brakes: Test service brakes and parking brake

- Lights: Check all lights are working correctly

- Horn: Verify horn operation

- Mirrors: Adjust for maximum visibility

SAFE OPERATION PRACTICES

Starting the Tractor

Correct Starting Procedure:

- Ensure tractor is on level ground

- Engage parking brake

- Place transmission in neutral

- Disengage PTO (Power Take-Off)

- Lower all implements to the ground

- Check around the tractor for people or obstacles

- Fasten seat belt securely

- Start engine following manufacturer's instructions

Prohibited Practices:

- Never start the tractor from outside the operator's seat

- Do not bypass safety interlocks

- Never start the tractor if any safety guards are missing

- Avoid starting in enclosed spaces without proper ventilation

Basic Operation Guidelines

Speed Management:

- Operate at a speed appropriate for conditions and terrain

- Reduce speed on rough ground, slopes, and in confined areas

- Maximum recommended speed: 37.5 km/h on flat, firm surfaces

- Minimum working speed: 2.8 km/h for precision operations

Steering and Turning:

- Avoid sharp turns at high speeds

- Reduce speed before turning

- Do not brake while turning sharply

- Be aware of the tractor's turning radius and rear overhang

Hitching Implements:

- Use only approved hitches and drawbars

- Hitch loads to the designated drawbar points only

- Never hitch to the rear axle or other non-designated points

- Ensure all pins and locking devices are properly secured

- Check that the hitch is within the tractor's weight capacity

Working on Slopes

Slope Safety Rules:

- Maximum Safe Slope: 25° (47%) for straight travel

- Maximum Turning Slope: 15° (27%)

- Always travel up and down slopes, not across

- Use the lowest appropriate gear

- Avoid sudden acceleration or deceleration

- Do not shift gears while on slopes

- Never engage neutral or coast downhill

- Keep loads low and centered

Warning Signs of Instability:

- Front wheels lifting off the ground

- Unusual leaning or tilting

- Difficulty maintaining direction

- Slipping or sliding tires

Power Take-Off (PTO) Safety

PTO Operation Guidelines:

- Ensure PTO guard is properly installed before operation

- Keep hands, feet, and clothing away from PTO shaft

- Do not wear loose clothing near PTO

- Disengage PTO before leaving the operator's seat

- Allow PTO to stop completely before connecting or disconnecting implements

- Use proper PTO shafts with safety shields

PTO Shaft Angle Limits:

- Maximum operating angle: 10° during straight operation

- Maximum angle during turning: 25°

- Never exceed recommended angle limits

TRANSPORTATION SAFETY

Road Travel

Legal Requirements:

- Register the tractor for road use if traveling on public roads

- Display appropriate license plates and lighting

- Follow all road rules and regulations

- Use hazard lights when traveling on roads

Transportation Preparation:

- Interlock left and right brake pedals

- Ensure all implements are properly secured

- Check height clearance for bridges and overhead obstacles

- Plan route to avoid low bridges and power lines

On-Road Operation:

- Maintain safe following distance (minimum 60 meters)

- Use turn signals well in advance

- Travel at appropriate speed for road conditions

- Be visible to other road users

- Avoid traveling during peak traffic times when possible

Implement Transportation

Implement Security:

- Lower implements to safe transport position

- Secure all movable parts

- Check that implements do not extend beyond legal width limits

- Use warning flags for wide loads

MAINTENANCE SAFETY

Routine Maintenance

Maintenance Safety Rules:

- Shut down engine and remove key before maintenance

- Allow engine to cool before working on hot components

- Use proper tools for the job

- Follow manufacturer's maintenance procedures

- Keep maintenance records

Common Maintenance Tasks:

- Oil Change: Every 100 operating hours

- Filter Replacement: Fuel filter every 200 hours, air filter as needed

- Lubrication: Grease all points as specified in manual

- Battery Maintenance: Keep terminals clean and tight

- Cooling System: Check coolant level and condition regularly

Hydraulic System Safety

Hydraulic Safety Precautions:

- High-pressure hydraulic oil can cause serious injury

- Relieve hydraulic pressure before disconnecting lines

- Use proper tools and wear eye protection

- Check for leaks before operation

- Replace damaged hoses immediately

Hydraulic Oil Specifications:

- Use only recommended hydraulic oil (AW 46)

- Change hydraulic oil every 1000 operating hours

- Keep hydraulic system clean and free of contaminants

EMERGENCY PROCEDURES

Fire Safety

Fire Prevention:

- Keep engine compartment clean and free of debris

- Regularly inspect fuel lines for leaks

- Avoid refueling near open flames or hot components

- Do not smoke while operating or refueling

Fire Fighting Equipment:

- Carry at least two fire extinguishers (ABC type)

- Know location and operation of fire extinguishers

- Have access to water source or fire hose

Fire Response:

- Shut down engine immediately

- Evacuate all personnel to safe distance

- Use fire extinguisher on small fires

- Call emergency services for larger fires

- Do not attempt to fight large fires alone

Rollover Emergency

If Rollover Occurs:

- Stay calm and stay in the protective zone of the ROPS

- Do not attempt to jump from the tractor

- Brace yourself for impact

- After the tractor stops, shut down the engine

- Exit carefully, watching for unstable terrain

- Do not attempt to right the tractor alone

Rollover Prevention:

- Always use seat belt when ROPS is in place

- Avoid steep slopes beyond recommended limits

- Operate at safe speeds

- Be aware of terrain conditions

- Keep loads low and balanced

Medical Emergency

First Aid Preparedness:

- Carry well-stocked first aid kit

- Know location of nearest medical facility

- Have emergency contact numbers available

- Ensure someone knows your work location and schedule

In Case of Injury:

- Secure the tractor (shut down engine, engage brakes)

- Administer first aid as needed

- Call for emergency assistance

- Do not move seriously injured persons unless necessary

- Provide clear location information to emergency services

ENVIRONMENTAL AND WASTE MANAGEMENT

Fuel and Chemical Safety

Fuel Handling:

- Refuel in well-ventilated areas only

- Do not smoke during refueling

- Use approved fuel containers

- Clean up spills immediately

- Store fuel away from ignition sources

Chemical Safety:

- Follow all safety instructions when using agricultural chemicals

- Wear appropriate PPE

- Store chemicals in designated areas

- Dispose of chemical containers properly

Waste Disposal

Environmental Protection:

- Do not dispose of waste oil, fuel, or chemicals on the ground

- Use leak-proof containers for waste fluids

- Recycle or properly dispose of batteries, filters, and other components

- Follow local environmental regulations

Waste Oil Disposal:

- Collect waste oil in approved containers

- Take to authorized recycling centers

- Do not mix waste oil with other substances

- Keep records of waste disposal

SAFETY CHECKLIST

Daily Safety Check

- Operator is trained and qualified

- PPE is properly worn

- Tractor is in good working condition

- All safety guards are in place

- ROPS is correctly positioned and locked

- Seat belt is functioning properly

- Fluid levels are correct

- Tires are in good condition and properly inflated

- Brakes are working correctly

- Lights and signals are operational

Before Operation

- Check weather conditions

- Plan work route

- Inform others of work location and schedule

- Check for hazards in work area

- Ensure communication devices are working

- Verify that no one is in the vicinity of the tractor

After Operation

- Park on level ground

- Engage parking brake

- Lower all implements to the ground

- Disengage PTO

- Shut down engine and remove key

- Clean tractor as needed

- Secure tractor against unauthorized use

- Record any issues or maintenance needs

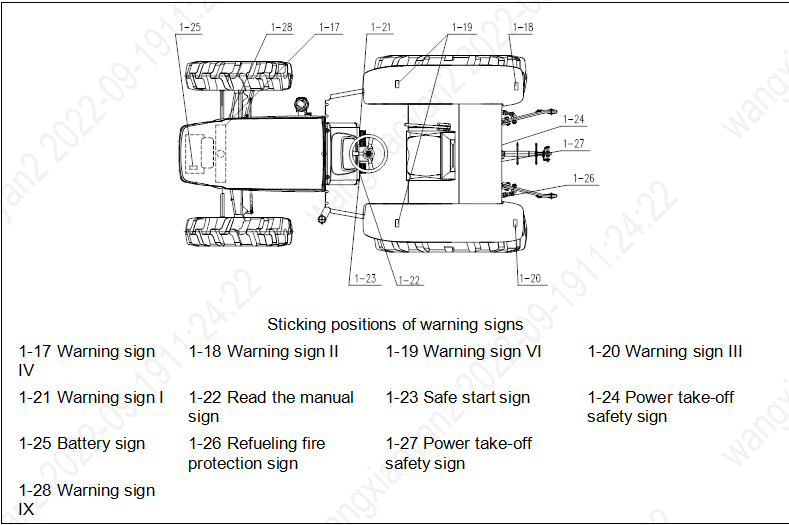

SAFETY WARNING SIGNS AND SYMBOLS

Common Safety Symbols

Warning Labels

- Keep all warning labels clean and legible

- Replace damaged or missing labels immediately

- Follow all instructions on warning labels

TRAINING AND SUPPORT

LOVOL Australia Support

Contact Information:

- LOVOL Australia Pty Ltd

- 123 Agricultural Drive, Sydney NSW 2000

- Phone: +61 2 9876 5432

- Email: safety@lovol.com.au

- Website: www.lovol.com.au

Training Services:

- LOVOL offers comprehensive operator training courses

- On-site training available for groups

- Refresher courses for experienced operators

- Specialized training for new technologies and implements

Authorized Service Centers:

- Network of authorized service centers across Australia

- Trained technicians for maintenance and repairs

- Genuine LOVOL parts available

- Emergency service available

CONCLUSION

Safe operation of the LOVOL F4000 tractor is a shared responsibility between the operator, employer, and LOVOL Australia. By following the guidelines in this safety guide, you can significantly reduce the risk of accidents and injuries.

Remember:

- Safety First: Always prioritize safety over productivity

- Be Prepared: Conduct proper inspections and maintenance

- Stay Alert: Be aware of your surroundings at all times

- Get Training: Ensure you have the necessary skills and knowledge

- Follow Procedures: Adhere to all safety protocols and guidelines

Your safety and the safety of those around you depend on your commitment to safe operating practices. Make safety a habit, not just a requirement.

Stay safe, farm smart, and enjoy the power and performance of your LOVOL F4000 tractor.