August 29, 2025 · 3 min read

As farming in Australia grows larger in scale and more technology-driven, tractors remain the backbone of agricultural productivity. They not only supply the pulling power for heavy-duty fieldwork but also provide energy for seeding, spraying, and livestock operations. For Australian grain growers and cattle producers alike, fuel efficiency has become a critical factor in managing costs across vast paddocks and long operating hours.

The Rise of CVT in Modern Tractors

Early tractors typically relied on mechanical gearboxes or hydrostatic drives, requiring constant clutching and manual shifting. While effective, these systems often led to wasted energy and operator fatigue. The introduction of Continuously Variable Transmission (CVT) technology has changed that. CVT allows for an unlimited range of gear ratios, giving operators smooth speed transitions without power loss or interruptions.

Although CVT concepts were experimented with as far back as the 1950s, they only gained traction in agriculture after automotive innovations made the systems more reliable and durable. Today, CVT-equipped tractors are valued in Australia for:

- Smooth operation across varying soil and terrain conditions

- Lower driver fatigue during long seeding or harvest runs

- Improved durability, reducing maintenance downtime

LOVOL CVT Tractors: Designed for Efficiency

LOVOL's CVT tractors are tailored for farmers who need both fuel savings and consistent field performance. By separating engine speed from wheel speed, the machine automatically adjusts to keep operations within the optimal fuel-use range. For example, in Australian broadacre cropping, where fuel costs can represent a large share of total expenses, this technology helps farmers cut operating costs significantly.

When combined with LOVOL's intelligent driving system, operators also gain more precision in planting and soil preparation, which translates into reduced labor requirements and more consistent results—key benefits for large farms spread across hundreds or even thousands of hectares.

Looking Ahead: Smarter and Cleaner Farming

The upcoming generation of tractor innovation will incorporate:

✅ Autonomous field operations (GPS navigation, AI-driven perception systems)

✅ Hybrid and full-electric drive systems for reduced environmental impact

✅ Versatile equipment platforms (modular implements, coordination with drones and robotic systems)

Bench Testing: Methodology & Results

Test Setup:

- Trelleborg tires (600/65 R28 front, 710/70 R38 rear)

- 40% liquid ballast

- Total weight: 12,280 kg

- Simulated load via a 340 HP tractor and force sensor

Key Findings:

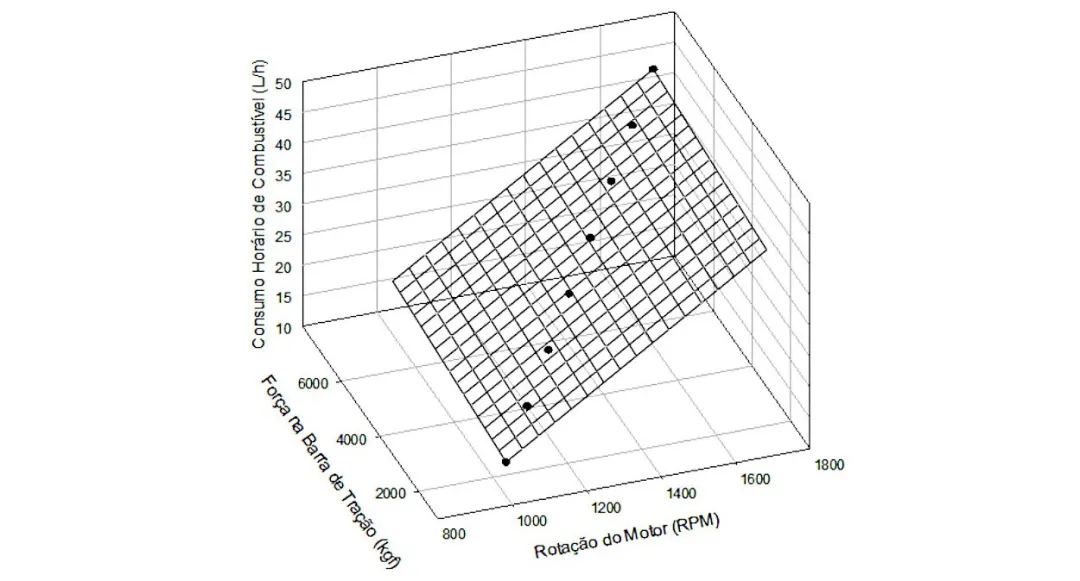

- 1. Fuel consumption rises with RPM (required for high torque).

- 2. Traction force directly impacts RPM: heavier loads demand higher engine speed.

- 3. CVT fine-tunes this relationship, minimizing energy waste.

A study by Alabi Oiole and Leonardo analyzed the link between engine RPM and hourly fuel consumption (HFC) on a New Holland T7070 tractor (167 kW, CVT).

LOVOL continues to innovate with powerful, efficient, and eco-friendly tractors—helping Australian agriculture move toward a smarter and more sustainable future.

Interested in LOVOL CVT tractors or farming solutions in Australia?

Click [Contact Us] for product details and local dealer support.